Product Categories

Exhaust Filtration / Diesel Particulate Filter Units

Various models available

Diesel Particulate Filter Units – Construction site equipment, such as forklifts, lorries, tractors, generators and compressors, emit dangerous levels of diesel fumes especially when being... read more

Diesel Particulate Filter Units – Construction site equipment, such as forklifts, lorries, tractors, generators and compressors, emit dangerous levels of diesel fumes especially when being used in confined spaces. It is therefore important to capture and filter these fumes at source, whilst continuously forcing fresh air into the work area. This makes sure that workers can continue their activities in a safe environment.

Excessive diesel fume exposure can result in anything from dizziness and fatigue, to kidney cancer and even death. Failure to conduct a suitable DEEE’s assessment and/or breach of COSHH regulations, will leave you in hot water with the HSE and may even land you in court.

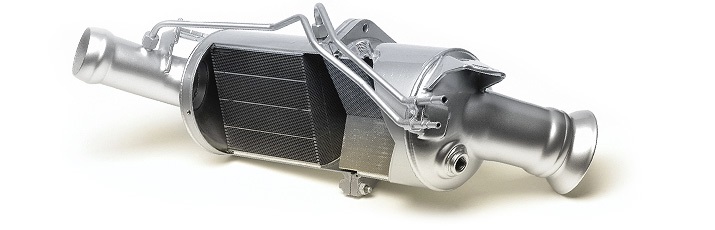

Diesel Particulate Filter (DPF)

Reduces particulate matter (PM) by up to 85%

Operates from engine start-up

Suitable for standby generator sets, low-usage forklift trucks, side-loaders, excavators etc.

Bypass system available

The diesel particulate filter collects the particulate matter in the exhaust stream by means of physical filtration. Effective from start-up, the filter is capable of retaining particles as small as 0.3 microns, trapping all PM10 and PM2.5 matter. DPF is also capable of reducing up to 85% of particulate matter (PM) in the exhaust stream.

Applications:

The filter is suited to low usage applications such as standby generator sets or on equipment being used for short periods at a time, it is particularly suited to equipment being used in confined spaces. The filters can be bypassed, so that it is only used when required, i.e. inside tunnels and warehouses, electronic or manual bypass valves are available.